ATA Cases

Custom ATA Cases & Shipping Crates for Equipment

Index Packaging, Inc., is a manufacturer of custom ATA flight cases, road cases, custom equipment cases, and shipping crates with foam inserts to securely hold your products during transit, ready in 3-4 weeks from design to completion. We specialize in custom-designed cases for transporting:

- Large medical devices

- A/V equipment: large screens, mixers, sound boards for events

- Digital musical instruments, e.g., large keyboards

- Microwave components

- Industrial equipment

- Aerospace parts

- Instrumentation – optics, magnetics, controls

- Trade show shipping cases

- Large, odd-sized equipment of any type

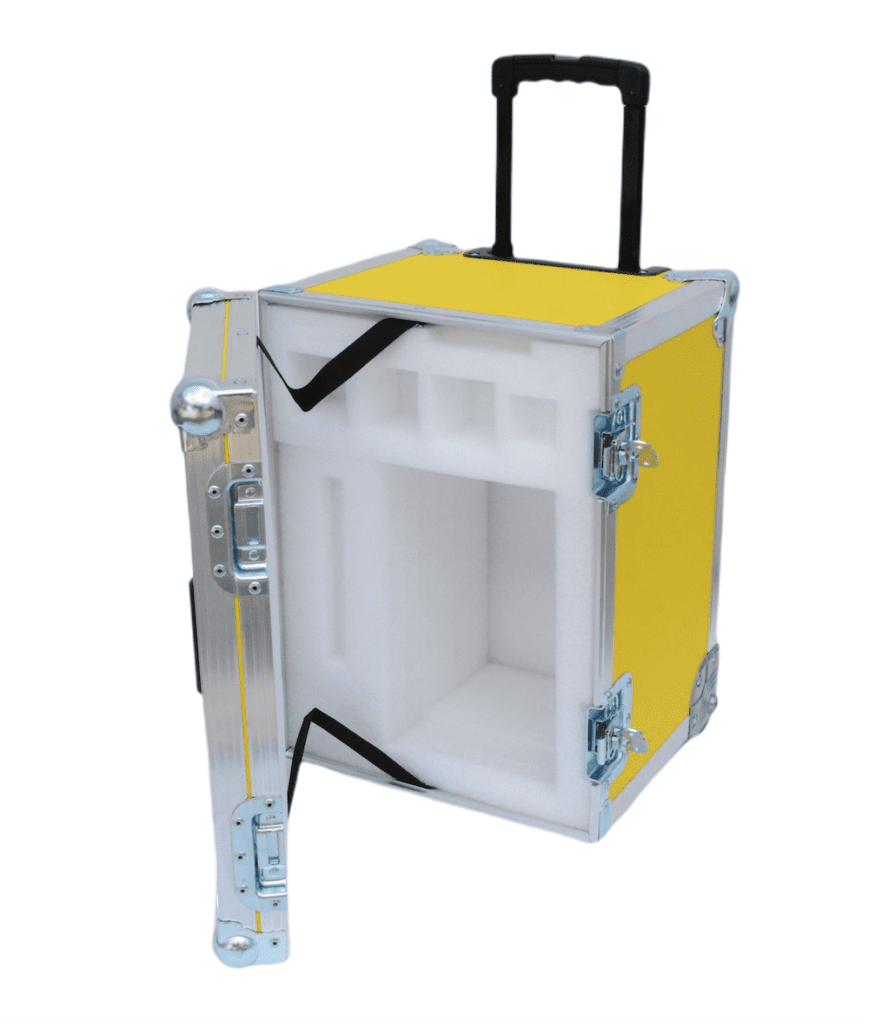

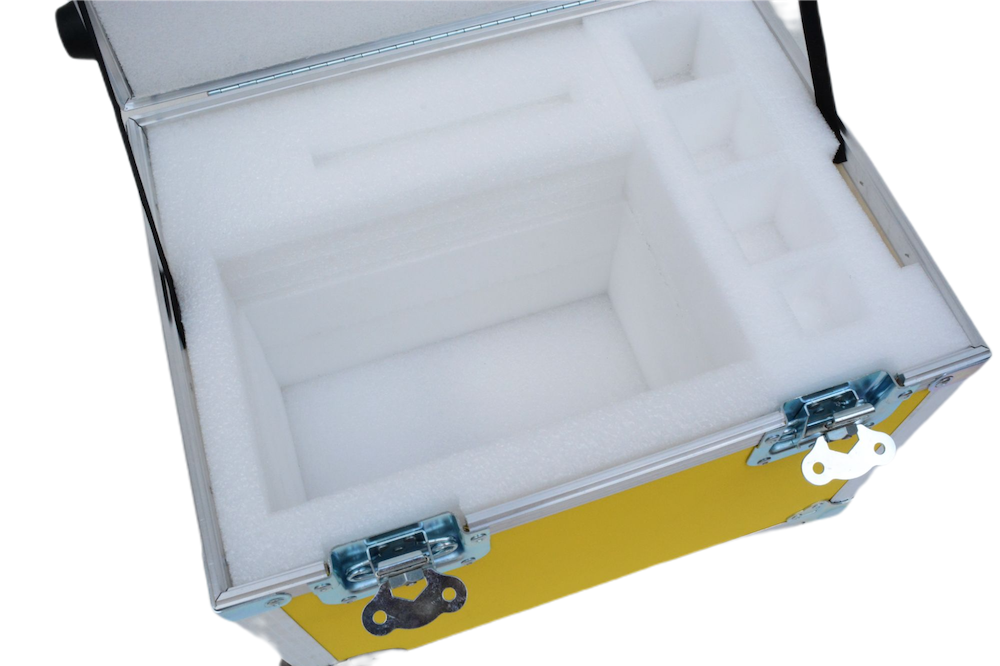

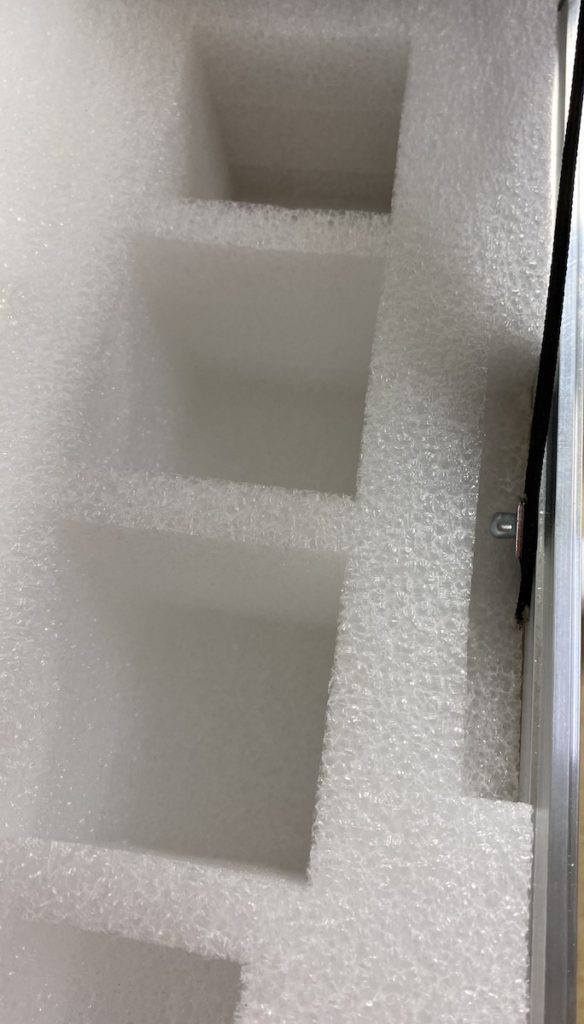

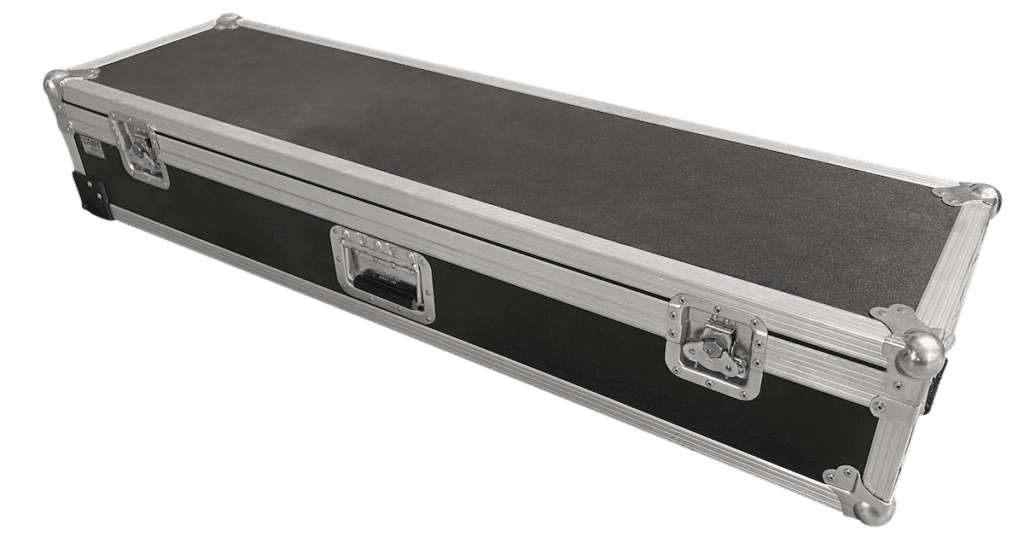

Our CaseX brand cases are crafted with proprietary construction methods and details that ensure the highest-quality protection with continuous double angle extrusion construction with staple fastening, not crimped. Every part of each case, including the foam insert, is designed and custom-made in-house to your specifications.

After collecting some initial information, we’ll proceed in four steps:

- Meet (on-site or via Zoom) to review your STEP files, product samples, or prototypes and gain a solid understanding of how your product is being shipped or transported so we can proceed with quoting and design.

- Design creation with CAD drawings as our deliverable, review process, and design approval.

- Sample/prototype development for testing.

- Full production and shipment.

Design & Engineering

Index Packaging Inc., has an in-house design team that provides full-product manufacturing drawings to customers to ensure the correct fit and function have been achieved before production begins. Product drawings include multiple views of your case—inside and out—to help you verify that all aspects of your case have been included in the final design.

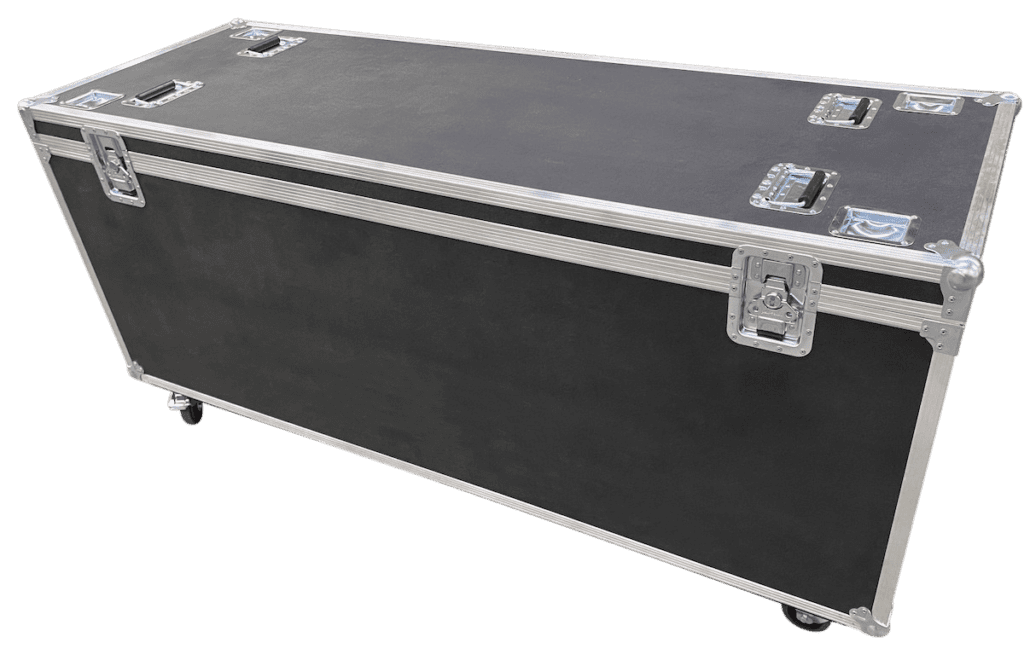

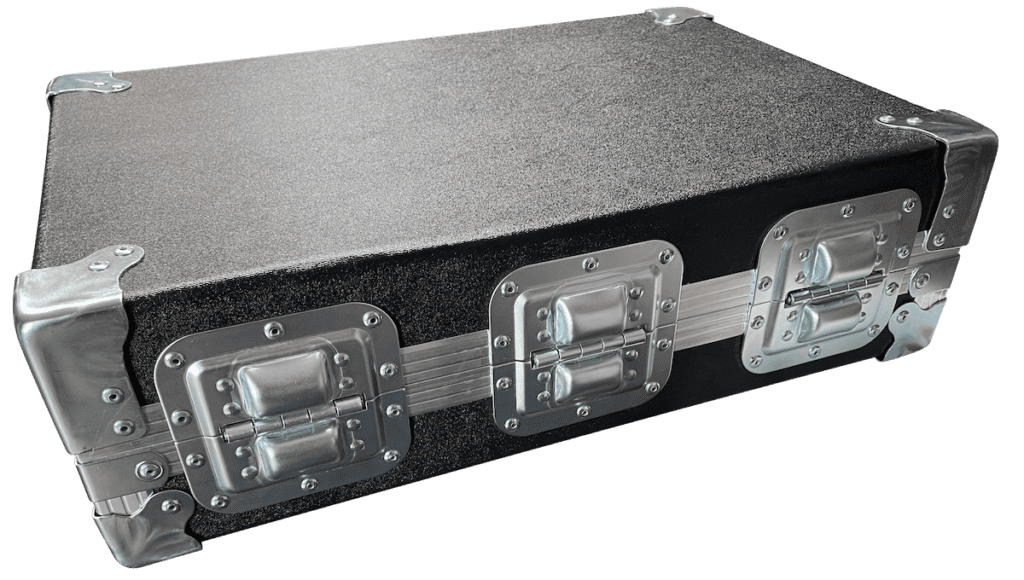

Case Construction

Cases are typically made with a laminate material consisting of ABS and high-grade plywood or lightweight fluted polypropylene (material details below), with aluminum edging and corner protection for stability and durability. Pull handles, chest handles, or casters may be added for ease of movement. All colors are available; however, a special-order minimum will apply to colors other than standard black.

Lead Time

We offer a 3-4-week turnaround time from initial design to completed product on all custom ATA cases that use standard hardware. Our own fleet of trucks can deliver directly to customers throughout New England.

Custom ATA Flight Case Styles:

Heavy-Duty

- Maximum strength, most durable case offered

- Many hardware options available

- ABS laminated to plywood

- Appropriate for solid-framed interior partitions

Lightweight

- Reduced weight

- ABS laminated to fluted polypropylene

- Solid strength and durability

- Limited hardware options

Ultra-Lightweight

- Lightest construction option available

- ABS laminated to fluted polypropylene

- Acceptable strength for lighter applications

- Limited hardware options

Get pricing, ask questions, or schedule an on-site visit by using the Request Quote form, or call to speak with a packaging specialist at 603-509-0009, Monday-Friday, 8:00 am-4:30 pm Eastern Time.